In modern manufacturing, efficiency and accuracy are essential for keeping production lines competitive and profitable. One of the most important machines helping industries achieve these goals is the liquid filler. Whether a company manufactures food products, cosmetics, chemicals, or pharmaceuticals, liquid fillers play a crucial role in speeding up production, ensuring consistent fill levels, and reducing the need for intensive manual labor. Over the years, these machines have advanced significantly, making them a must-have for manufacturers wanting to improve productivity. This article explores how liquid fillers transform manufacturing operations and why they are essential for businesses that want to scale efficiently.

1. Reducing Manual Labor and Human Error

Before automated filling machines became common, companies relied heavily on manual filling methods. This process was slow and often led to inconsistent product levels, spills, or wastage. With liquid fillers, manufacturers eliminate most of these challenges.

Liquid fillers reduce the need for manual handling by performing repetitive filling tasks automatically. Operators no longer have to measure each container by hand, saving significant time and minimizing fatigue-related errors. By reducing human involvement, the chances of underfilling, overfilling, or contaminating products drop dramatically. This not only boosts productivity but also enhances overall product quality.

2. Increasing Production Speed

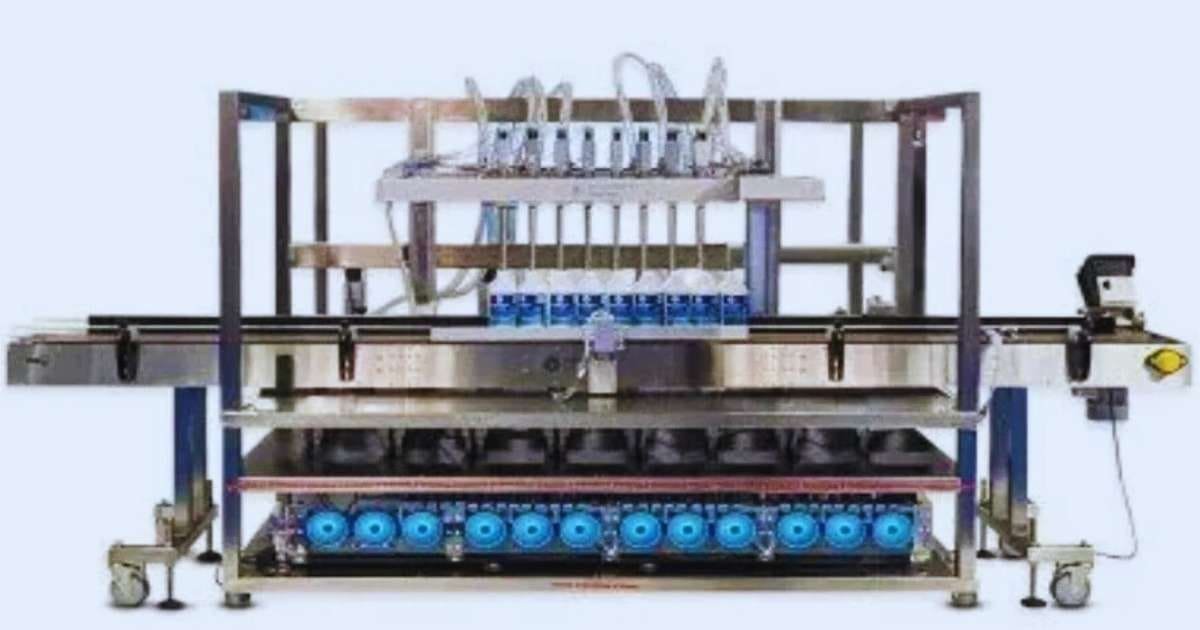

One of the biggest advantages of liquid fillers is their ability to fill hundreds or even thousands of bottles, jars, or containers in a short period. Depending on the machine type — whether automatic, semi-automatic, or high-speed rotary systems — liquid fillers can drastically increase throughput.

Automatic liquid fillers can handle continuous production, filling multiple containers at once with precise calibration. This means companies can produce more units per hour compared to manual or traditional filling devices. As demand for packaged products rises globally, faster filling technology allows manufacturers to meet production targets without expanding their workforce.

Also Read This: Little Minaxo: How to Choose a Certified Technician for Your Refrigerator Repairs

3. Ensuring Consistent and Accurate Filling

Consistency is key in manufacturing, especially for products like beverages, chemicals, oils, syrups, cosmetics, or pharmaceuticals. Overfilling leads to product wastage, while underfilling can create compliance issues and customer dissatisfaction.

Modern liquid fillers use advanced technologies such as:

- Volumetric filling

- Piston filling

- Gravity filling

- Vacuum filling

- Pump-based systems

These systems are designed to deliver high accuracy, ensuring that every container receives the exact required amount. By maintaining consistency across all units, manufacturers improve brand trust and reduce unnecessary product loss.

4. Minimizing Product Wastage

Wastage is a common problem when filling products manually. Spills, overflow, and inconsistent measurements can lead to significant financial losses—especially when dealing with expensive formulas like pharmaceuticals or high-value cosmetics.

Liquid fillers come with features such as anti-drip nozzles, precise volume controls, and advanced sensors that prevent overflow. These components help ensure that almost no product goes to waste during the filling process. As a result, manufacturers can use their raw materials more efficiently, improving profit margins and reducing environmental impact.

5. Supporting a Wide Range of Products and Viscosities

Another key way liquid fillers boost productivity is through their versatility. These machines can handle a wide range of liquid types, including:

- Thin liquids like water and juice

- Medium-thick products like oils and syrups

- Thick or viscous materials like lotions, gels, creams, and detergents

This flexibility allows manufacturers to use the same machine for different product lines by making minor adjustments or changing filling nozzles. Instead of investing in separate equipment for every new formulation, businesses can rely on a single liquid filler to handle multiple tasks, increasing efficiency and reducing operational costs.

6. Enhancing Hygiene and Product Safety

In industries like food, pharmaceuticals, and cosmetics, hygiene is a top priority. Liquid fillers are designed with this in mind. Many machines are constructed using stainless steel and food-grade components, ensuring that they are easy to clean, sanitize, and maintain.

Features like closed filling systems, clean-in-place (CIP) capability, and contamination-free nozzles ensure that the product is never exposed to the environment during filling. This helps manufacturers maintain high product safety standards while complying with strict industry regulations. Efficient hygiene management reduces downtime, allowing production lines to remain active more consistently.

7. Seamless Integration Into Production Lines

Modern manufacturing often involves integrated systems where multiple machines work together—such as conveyors, cappers, labelers, sealers, and packaging stations. Liquid fillers are designed to integrate effortlessly into these automated production lines.

When properly integrated, the liquid filler becomes one component of a continuous workflow. Containers move from one stage to another without interruption, improving overall speed and reducing bottlenecks. Manufacturers can scale production simply by adjusting speeds or adding additional nozzles, rather than overhauling the entire setup.

8. Lowering Long-Term Operational Costs

Although purchasing a liquid filler requires an upfront investment, the long-term savings are significant. By improving accuracy, reducing wastage, and minimizing labor costs, businesses can lower their operational expenses.

Maintenance costs are also lower because modern liquid fillers are built with high-quality materials and designed to run for extended periods. With the right servicing schedule and occasional replacement of minor parts, the machines can function efficiently for years, offering excellent return on investment.

9. Improving Overall Workflow Efficiency

Liquid fillers don’t just enhance the filling stage — they improve the entire workflow. By reducing manual intervention, preventing delays, and ensuring consistent output, they allow manufacturers to plan production more effectively. This leads to smoother operations, fewer stoppages, and easier forecasting of supply needs.

Workflow efficiency also improves employee morale. Instead of performing repetitive manual filling tasks, workers can focus on supervision, quality checking, and other skilled roles. This shift helps companies build a stronger, more skilled workforce.

Conclusion

Liquid fillers are essential machines in modern manufacturing. Their ability to improve accuracy, reduce labor, boost production speed, and maintain consistency makes them indispensable for companies looking to increase productivity. Whether you operate a small business or a large-scale manufacturing unit, investing in the right liquid filler can transform your production capabilities. By integrating advanced filling technology, manufacturers can meet growing demand, maintain high product standards, and stay competitive in a fast-paced market.